Step 1: Extracting the coffee beans

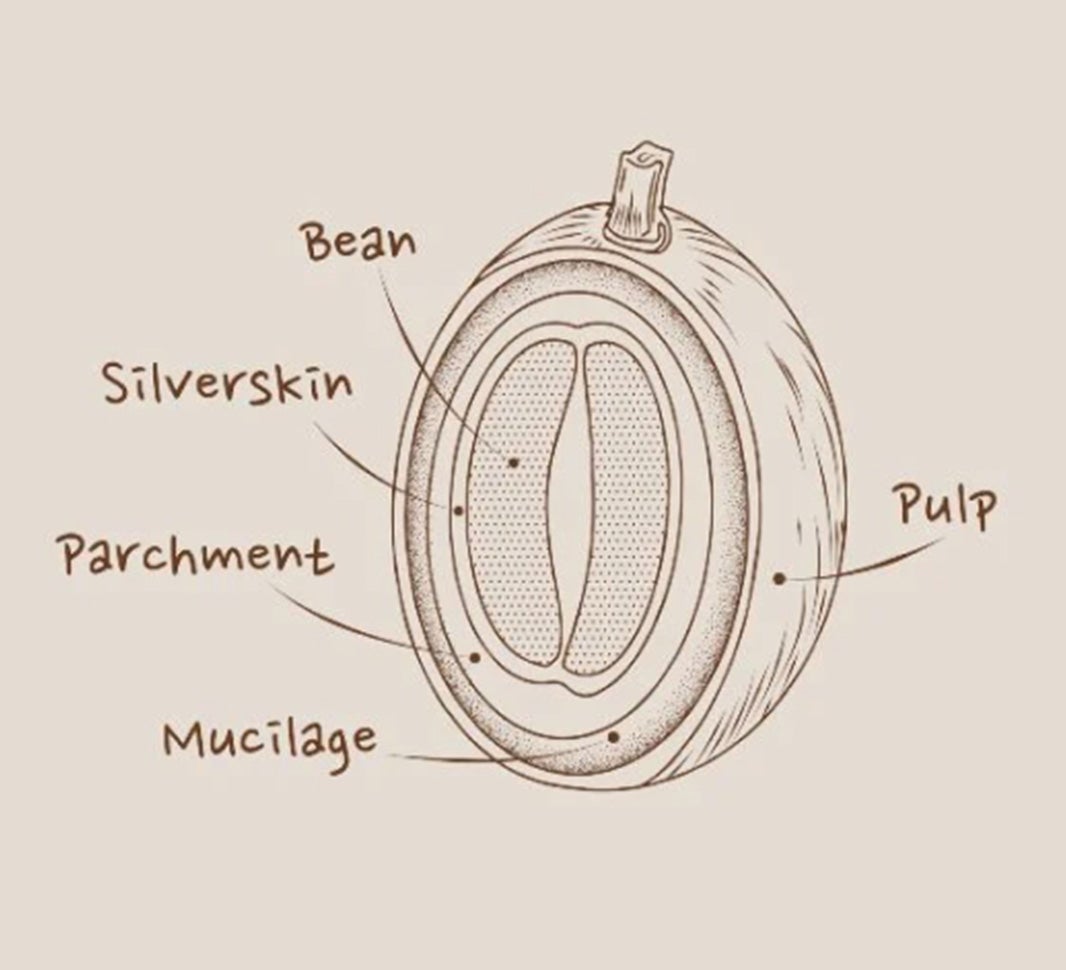

Understanding the 6 coffee layers

Outer Skin / Exocarp: Coffee seeds are covered by flesh, much like a regular cherry. At the beginning of fruit development, this outer layer of the coffee cherry is green. As the fruit matures, it turns yellow, then orange, and finally a ripe red.

Pulp / Mucilage / Mesocarp: The next layer of the coffee cherry is common in many seeded fruits. It’s a sweet sticky layer covering each of the coffee seeds, rich in sugars and has a big influence on the taste of the coffee bean.

Pectin: This is responsible in protecting the coffee beans. It’s made up of a cellulose layer.

Parchment / Endocarp: A thick shell-like layer that surrounds the bean and when dried, loosely resembles parchment paper.

Silver Skin / Chaff: A very fine layer with a silver sheen to it, which is where the name originates. This layer remains on the seeds (coffee beans) and is removed by the roasting process. It can often be referred to as chaff.

Seed / Coffee Bean: The beautiful green coffee bean or seed, while still inside the cherry, matures to become the coffee we all know and love, once it’s roasted to perfection.

When coffee beans are dried naturally, they give fruitier flavours due to the fermentation of natural sugars. A washed process removes all the fruity sugars leaving a pure, stronger coffee flavour.

Step 2: Preparing the coffee beans

Before the coffee beans are roasted, they must go through a special preparation stage, which can be done through either a washed or a natural process.

Dry/Natural Coffee Process

Dry process, also known as unwashed or natural coffee, is the oldest method of processing coffee. After harvest, the entire cherry is cleaned and placed in the sun to dry on tables or in thin layers on patios. The natural/dry process refers to when the bean is dried in the cherry before de-pulping. De-pulping is the process of separating the coffee seeds from the outer layer of flesh. After coffee cherries are picked, they must be de-pulped within 24 hours. If the cherries pass the 24-hour mark without being de-pulped, they may produce an overly fruity, rotten flavour that can ruin the quality of the coffee.

Wet/Washed Coffee Process

The washed process is where the beans are dried without the cherry, de-pulped and then they are usually fermented to help in separating the rest of the pectin from the bean and parchment, then finally, the beans will be washed and cleaned before drying. In the wet process, the fruit covering the seeds/beans is removed before they are dried. Coffee processed by the wet method is called wet processed or washed coffee. The wet method requires the use of specific equipment and substantial quantities of water.

The coffee cherries are then sorted by immersion in water. Bad or unripe fruit will float, whereas the good ripe fruit will sink. The skin of the cherry and some of the pulp is removed using a machine, by pressing the fruit in water through a screen. The bean will still have a significant amount of the pulp clinging to it that needs to be removed. This is done either by the classic ferment-and-wash method or a newer procedure variously called machine-assisted wet processing.

Believe it or not, this preparation before the roasting process does affect the taste! When dried naturally, you can expect fruitier flavours due to the fermentation of natural sugars in the pulp. A washed process however, offers more vibrant flavours. This is because it removes all the pulp and fruity sugars which have an impact on the bean, leaving the pure coffee bean flavour to come through more strongly.

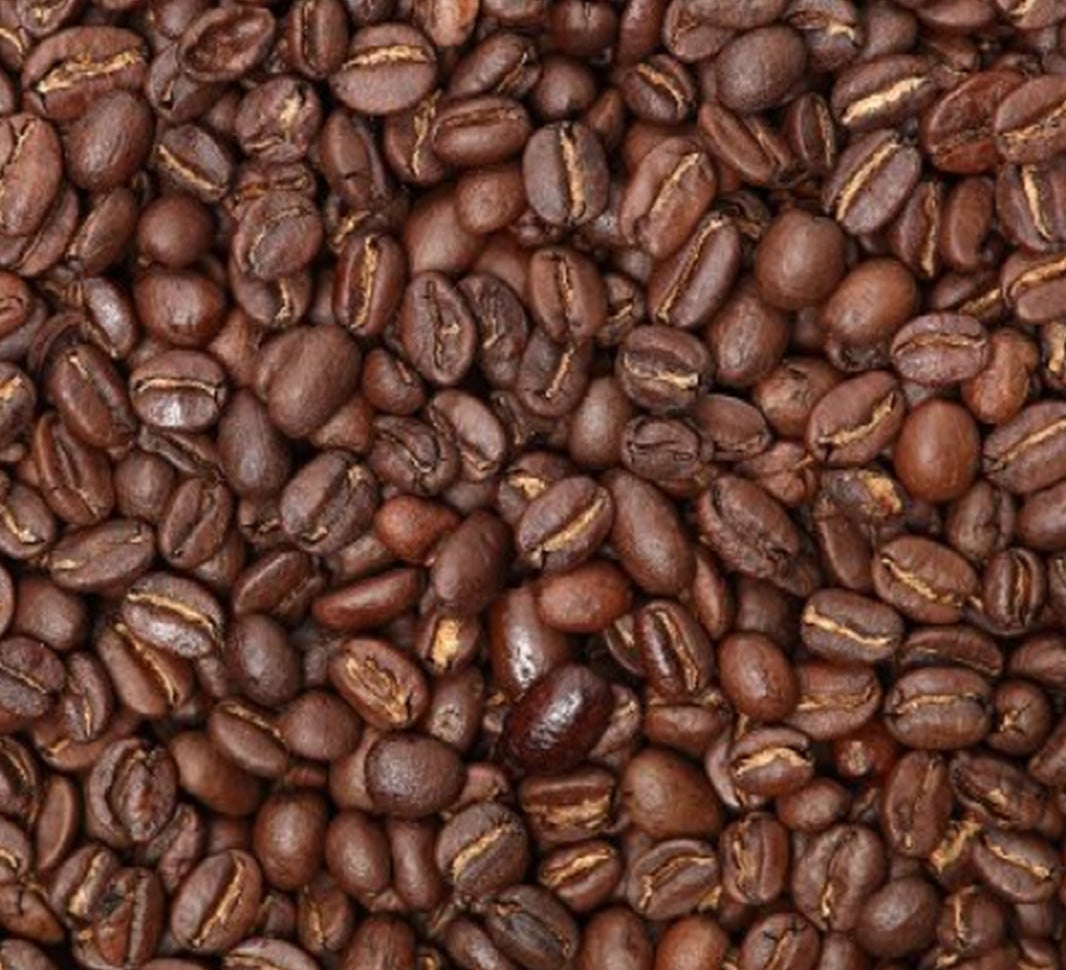

Step 3: The roasting process

Interestingly, coffee beans are originally green with a grassy smell! The rich, brown colour, wonderful flavours and aroma we all enjoy are in fact due to the careful roasting process they undergo after harvesting. Once the beans are put inside the drum of the coffee roaster and they begin to heat up, the process causes a chemical change in the beans as they’re brought to a high temperature very quickly. Then, once they reach the ideal temperature for that particular roast, they get cooled rapidly in order to stop them being roasted further. The process may sound relatively simple, but it requires a keen eye to ensure they’re roasted to the correct standards.

Find out more about the coffee roasting process in our guide.

Types of Coffee Roast

There are four common types of coffee roasts, all with their own unique flavours and notes which are brought out at different stages of the roasting process.

1. Light roast coffee

Light roast coffee is also known as the ‘first crack’ due to the fact that the beans are at the first stage of expanding and cracking. This type of coffee roast is when the beans reach an internal temperature of between 180°c - 205°c and are very light in colour and dry with absolutely no oil present on the surface. The flavour profile will be quite acidic but you can also expect fruity notes and a more aromatic experience too.

For the most sophisticated of taste buds, try our NESCAFÉ® GOLD Roastery Collection Light Roast. Sweet with notes of rich caramelised honey and toasted biscuit, our master roasters combine 50 years of craft and smart roasting technology to create this unforgettable blend.

2. Medium roast coffee

As the name suggests, medium roast coffee is medium brown in colour, dry and generally more balanced in flavour. This type of coffee roast is roasted to a temperature of between 210°C - 220°C and is preferred by many as the flavour, aroma and acidity all entwine in a harmonious blend and often, a slightly sweeter taste and stronger aroma can be expected too.

If a more balanced flavour and aroma is appealing to you, try our NESCAFÉ® GOLD. It's smooth, rich, yet well-rounded. Or, perhaps NESCAFÉ® GOLD ESPRESSO is for you, with its irresistible velvety crema.

3. Medium-dark roast coffee

With the coffee beans reaching a temperature of between 225°c - 230°c, medium-dark roast coffee is a great option for those looking for something a little stronger in flavour than medium, but not quite as bitter as dark roast coffee. Darker in colour and with oil present on the surface of the roasted bean, this type offers a rich flavour that’s described as almost bittersweet. Additionally, thanks to the extended roasting period, the acidity is virtually undetectable.

If you like your coffee beans rich in aroma and full-flavoured, try our NESCAFÉ® Classic. Made with perfectly roasted medium-dark coffee beans for a well-balanced flavour profile that’s universally loved.

4. Dark roast coffee

The boldest roasting profile available, dark roast coffee is roasted to a temperature of between 240°c - 250°c. This type is black in colour with an oily surface and a very bitter taste. The flavours are very pronounced with strong notes and often, hints of caramel can be found in these types of coffee roast.

Medium-dark and dark roasted coffee beans go through what is known as ‘second crack’, relating to an occurrence during the roasting process. ‘First crack’ is when the coffee beans will audibly pop like popcorn or puff up slightly, whereas ‘second crack’ is a slightly softer sound. It means that if the roasting process continues long enough, coffee beans will go through a second crack, which is usually caused by the oils beginning to migrate from inside of the bean to the outside.

For those who like a dark roast coffee, our NESCAFÉ® GOLD Roastery Collection Dark Roast coffee is just for you. With notes of dark chocolate and roasted nuts for a rich and intense flavour, you will not be disappointed.

Knowing more about your coffee roast will awaken your senses, making every cup you enjoy that much more rewarding. Want to find out more about your brew? Read about the rich history of coffee.

Today’s community favourites